As we wrote about previously, lean manufacturing consulting firms in China need to overcome many cultural obstacles in order to get factories to perform at the same level as their North American and European counterparts. If you have a hard time convincing your Chinese suppliers or the managers inside your company to work with consultants, this article will be useful. Here, we will cover how these cultural obstacles discourage buy-in on manufacturing consulting, and what you can do to make it easier for Chinese manufacturers to see the value of getting a consultant.

5 Major Obstacles for Manufacturing Consultants in China

1. Lack of awareness of best practices

Consultants have to careful when speaking to factory managers in China, because many managers have never been to a great manufacturing facility or never read a book on the subject.

They may already be happy where they are and take pride in their production output. To them, the best factories are those that are fully automated. Period.

When we are not careful about what we say and how we say it, we may be perceived as sleazy, saying anything to make a sale. Here are a few examples of things we need to be careful about when speaking to them:

- ‘The ratio of indirect to direct workers should be 1:10' when they have close to 1:1.

- ‘Some factories have 400 inventory turns’ when they have 10 and are happy about it.

- ‘Your best-in-class competitors can change over the dies on this press in 6 minutes’ when their technicians take 10 hours.

2. Reluctance to pay for services

Based on our observations, Chinese people always want to get something tangible for their money.

- They travel abroad? They want photos of themselves in famous places.

- They sign up for training? They want a certificate.

- They go for a cooking class? They want to leave with a cookbook.

However, with consulting services, envisioning a tangible result is always a challenge.

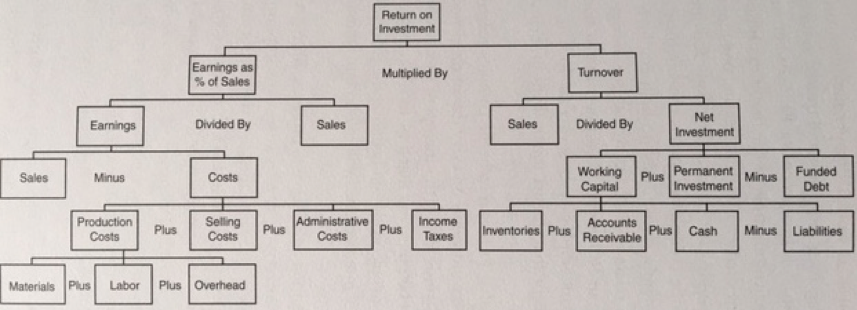

While ISO 9001 consultants often promise an official registration, manufacturing consultants often need to put in a lot of effort to convince factory management that their operations are not functioning as well as they think. The positive results of consulting are not always as straightforward and, unfortunately, management seldom understands all the drivers of profit in their company.

It is difficult for them to imagine how great consultants can benefit them.

3. Short-term orientation

Factory owners tend to see operators and middle managers as disposable and replaceable. Working hard on implementing new processes and systems for 6 months is not an enticing value proposition, especially when it implies a lot of training in those new processes and systems. "Why train them since they will leave soon?", the reasoning goes.

Many do not understand that training and engaging employees on matters related to process improvements are key to improving employee retention. And that retaining employees saves them time, money and effort in the mid- and long-run.

4. The quest for shortcuts

Again, hard work on a project is not exciting. In contrast, opening a catalog and picking a fresh new piece of equipment is fun. Automation salespeople can paint a rosy future and deliver it very soon (contingent on payment) and at no pain. That sounds much better than leading the organization through an ambitious initiative that takes month to show results. However, it may cost the company more without them realizing it.

I remember a former consultant who told me their clients expected him to open his briefcase and pull out a 'magic wand’. That’s often what we need to face with Chinese manufacturers.

5. Negative past experiences

We often hear “we had a bad experience with a consultant in the past." And it is no surprise. The number of salespeople who promise the moon, extract 200,000 RMB, and deliver nothing are endless.

A negative past experience makes selling manufacturing consulting services much harder. The key is to show that the approach is entirely different and that you deliver results.

How to Convince your Chinese Factory to Invest in Manufacturing Consulting

1. Translate everything into RMB

Be prepared for training key managers to understand the links between process improvement and “cash in the bank” (which is what the average factory owner cares about). Here are a few examples:

- Tons of valuable inventory = millions that could be in your bank account.

- Scrapped material = thousands of RMB thrown away

- Poor maintenance = machines with a shorter lifetime (say, 20,000 RMB lost on each one) + many production breakdowns (thousands of RMB a month).

Another unit of comparison is “this lost customer used to bring in a profit equivalent to 1 apartment + 1 BMW every year”. With that point of comparison, it is easier to understand the value of specific efforts. People will listen!

2. Show how improvements will lead to more customers

Chinese companies are happy to invest money if they think they will get new business. Look at how much Alibaba.com, the Canton Fair, Global Sources, and others spend on their marketing, as well as into hiring a large army of salespeople.

For many companies, the best motivator is a large customer who says “I will double your business if you cut your lead time in half / improve quality / set up a good production planning system."

3. Show that the consultants are professional and know much more than their team

A consultant-client relationship can quickly become a student-professor relationship in China. It can be a good thing as long as the consultant doesn’t see themselves as a superior and focuses on getting the work done.

4. Start small and get some quick wins

Don’t ask for a leap of faith. Promise results in 2-3 months first, and deliver them. Chinese managers are very pragmatic – they believe what they see. If factory consultants deliver measurable savings, clients are happy, whatever country they are in!

5. Show a proven consulting process

As you meet with resistance and doubt, it helps to invoke a time-tested process. This is what we have developed over time at CMC, and it does help a lot.

To sum up, Chinese companies approach consulting services in an entirely different way, which means the whole engagement process needs to be completely different.

Have you managed to convince a Chinese company, maybe one of your suppliers or partners, to work with a manufacturing consulting firm? How did it go?