The Value Stream Map (VSM) is one of the most common “Lean tools” mentioned by books and consultants, including at CMC. But learning how to draw or read a VSM takes time and effort.

In this post, we'll show you how it's done.

What Is A Value Stream Map?

A VSM makes the flow of information and materials visible. Its purpose is to show where some of the waste lies in the system and to plan for changes that will improve the whole system (not only one specific process). In short, it helps get close to the just-in-time (JIT). It is too easy to get bogged down in the specific conventions of value stream mapping symbols (which are not always intuitive and, for some of them, take a long time to draw).

We developed a step-by-step approach to drawing a basic VSM that focuses on essential information.

7 Essential Tips for Creating A Value Stream Map

1. Draw A Simple Flow Chart First

The most important aspect of a VSM is the visualization of the steps in a process. If you are new to value stream mapping, do not try to draw your first full map while getting familiar with a process. Pick one product and follow the materials physically from arrival in your facility to departure to customers (which might be another facility within your group).

Here are a few examples of steps to show on the flow chart:

VSM Steps Examples

- Getting a sale order from a customer

- Entering that order in the IT system

- Sending POs to suppliers for the materials

- Shipment from suppliers

- Receipt in incoming warehouse

- Incoming QC

- Cutting

- Heat treatment

- Machining

- Inspection

- Packing

2. Don’t Restrict the Scope of Your Study

You want to visualize the steps of a process, ideally through the whole supply chain. You might want your VSM to focus on what happens within your walls, but it is always good to show what happens in the end-to-end supply chain on a more macro scale.

For those who have read Lean Thinking, you will remember the example of Tesco, the British supermarket chain, studying all the steps necessary to make an aluminum can of soda from the Australian mine to the smelting factory in Scandinavia until the supermarket aisles in the UK. Getting a bird’s eye view of what happens in the entire supply chain is an excellent first step before delving deep into a VSM.

3. Collecting More Data & Starting the VSM

Show a box for each process step.

Most likely, you will need to go back to observe each process step and evaluate the following metrics:

- Cycle time (how many seconds it takes to process 1 piece)

- Changeover time (how many seconds it takes between the end of processing one product type to the first sound processing of another product type)

- Uptime (what percentage of the time is the process up and running?)

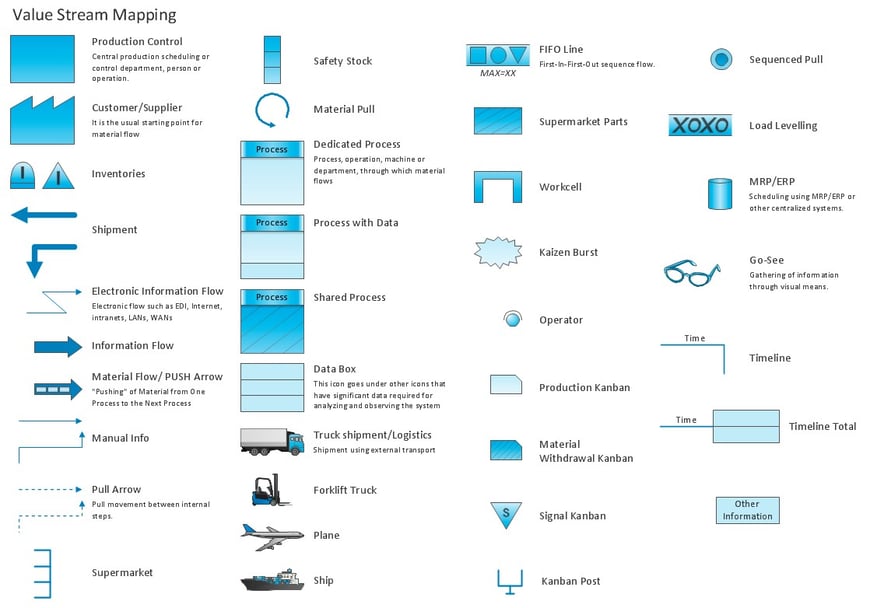

4. Most Common VSM Symbols

One downside of VSM conventions is the number of symbols to learn. A best practice is to put a VSM on the wall and share it with everybody, but the special symbols make it hard for people to understand what is communicated. Be prepared to give explanations.

Here is a great overview of the most common VSM symbols:

Source: http://www.conceptdraw.com/How-To-Guide/picture/VSM-symbols.png

5. Learning All the Details of A Good VSM

This article won't explain the concepts of a supermarket, pull vs. push, central production planning vs. Kanban vs. linked and flowing processes, etc. We also don't go into the differences between a VSM of production processes and one of office work (and how to make them coexist on the same map). Instead, we will point to two good books on the subject.

- For manufacturing environments (restricted to production activities): Learning To See

- For admin/office environments: The Complete Lean Enterprise: Value Stream Mapping for Office and Services

These two workbooks go deep into a few value stream mapping examples.

6. Go The Extra Mile

So far, we expect you to have mapped the process steps in pencil on a large piece of paper while observing processes and “following” a product. Do you need to show that VSM in an excellent report, in a soft copy? There are now quite a few professional solutions, and here are three popular ones.

- Lucidchart has a VSM toolbox and is an easy-to-use and inexpensive solution

- Visio (by Microsoft), the most commonly used in big companies

Quality Companion (by Minitab), a serious competitor to Visio for manufacturing-related diagrams

7. Take Some Liberties

Add extra information if you have space on your map and think it is desirable. One example is human movement (in case some operators have to walk from one process to the next). Most mentors would be thrilled to see their mentee appropriate a tool to the point where they become creative and add to it!

Was this useful? Have you got other tips to share? We hope you can leave a comment about your experiences with value stream mapping below for our community.