1. Select critical-to-quality (CTQ) product characteristics

For example, if the metal hardness is lower than expected on a screwdriver, that product might not be able to perform its intended task. Hardness is a CTQ characteristic.

Before we break down the steps, we first need to understand what Statistical Process Control (SPC) is. SPC can help a factory measure and control quality by gathering data to monitor the production process. It not only allows factories to operate at its highest capacity but also sets the foundation for continuous improvement.

While SPC can help control processes and ensure consistent output, many of China’s factories seldom apply it.

To understand how this tool works, it is best to follow the logical steps in its implementation in a factory:

For example, if the metal hardness is lower than expected on a screwdriver, that product might not be able to perform its intended task. Hardness is a CTQ characteristic.

What qualifies a process as “critical”? If something goes wrong with that process, it will probably have a sizable impact on at least one CTQ characteristic.

Critical processes are often indicated with a ‘*’ on the control plan.

Many modern pieces of equipment collect and analyze data, and then issue an alert when they get out of control. However, this is very uncommon in China, so let’s assume this is not the case; it means you will need to carry out steps 4 and 5.

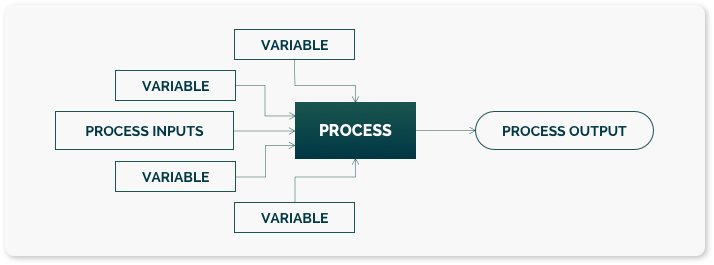

Based on this, you might conclude that the viscosity of the glue and the ambient humidity are two variables that need controlling.

But how can you get that information? It often comes from engineers, chemists, physicians, etc. but it can also come from operators who have been working on that process for some time and may have noticed some cause-and-effect relationships.

For more information on this step, ‘Reducing Production Costs’ by Don Wheeler is an excellent resource.

There are 2 ways you can ensure that your production does not deviate too much:

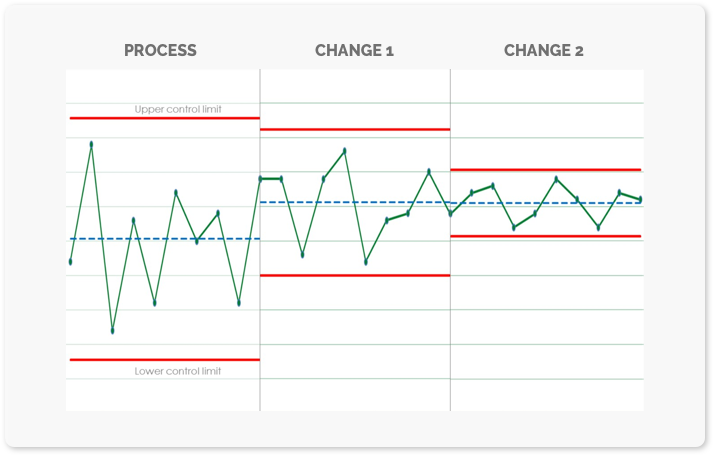

Now that you have made variations visible, the next step is to find ways to reduce it. If you use statistical process control charts, ideally it looks somewhat like this:

As long as the Cpk index is within the control limits, engineers and production leaders are encouraged to test different approaches. A Cpk target of 1.0 is often attainable within a few weeks. 1.33 is more challenging. 1.66 is much, much harder!

If necessary, you can use another statistical technique called Design of Experiments (DoE) to help you get close to the optimal values for variables that impact your process output. But, be prepared – there are several available approaches here, and it can get relatively complex.

Let’s say you manage to reduce variation. Set a new target, and keep controlling the key variables. If your process characteristics drift in one way or another, your statistical process control system will alert you. Otherwise, don’t tamper with the process, constant little adjustments will mechanically make the process “unstable” in statistical terms.

Despite the relative simplicity of implementing SPC, it is rarely realized in factories across most industries in China. In most instances, factories would benefit from enforcing SPC, would yours?

For more information on how your factory can save on costs and improve quality, download our FREE eBook below.