What is the single most important principle that a manufacturer should start applying, if they want to improve quality and safety? The root cause analysis, coupled with root cause correction. Unfortunately, generations of buyers have been frustrated by the inability of most Chinese managers to apply that principle.What is missing?

- Adequate on-the-job training.

- A simple method to follow, which does not call for inductive reasoning (I think that's the reason why the "5 why" and "fishbone diagram" tools are not used effectively in China).

- A focus on the system rather than the people ("worker was lazy" is not the real root cause).

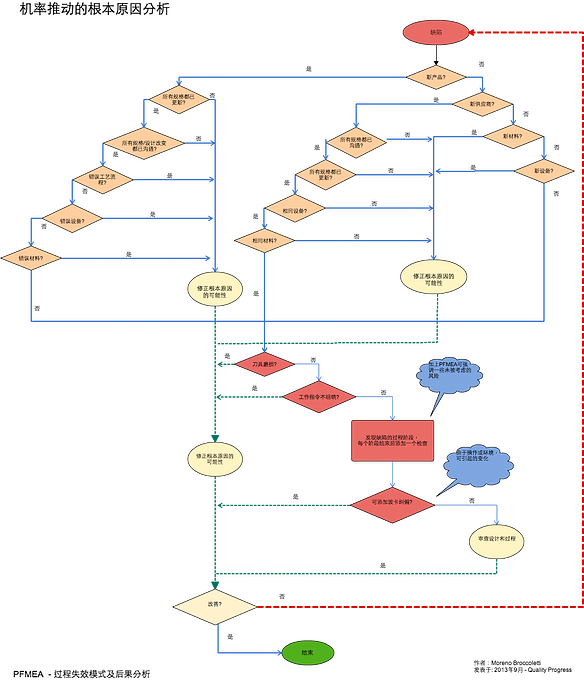

Here is a simple flow chart that, if applied regularly to problems, can bring excellent results:

Source: “Probable Cause, Using probability to get to the bottom of the issue”, published in Quality Progress of Sept. 2013 by Moreno Broccoletti — registration required). See its English version here.