This is our second article of 3 concerned with pollution in China. Let's look at what buyers should do in the wake of the government’s increase in anti-pollution inspections in China...

In Predicting Painful Factory Closures in China: a Case Study we gave an example of product that is made up of 2 components, each one made by using processes that are potentially highly polluting.

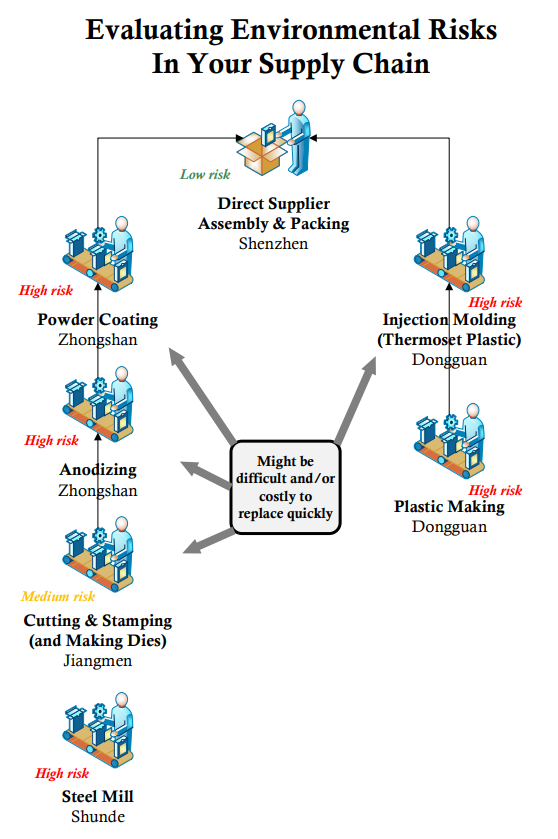

The good news is, you don’t need to know all the details of those sub-suppliers and you don’t need to visit them in order to have a first evaluation of the situation. You can ask your direct suppliers for some information that will help you pinpoint 4 risk factors in your supply chain caused by pollution. Let’s go through them one at a time:

1. Get the list of processes involved in making your product

Ask your direct supplier to list the operations and the cities in which they are carried out.

It should allow you to draw the same type of graph as we showed in our case study:

It might be extremely simple for a pair of socks and extremely complex for an entire motorcycle. If it is not practical, focus only on the components that are not easily replaceable.

2. Any chemicals involved?

If they are buying chemicals, you need the material safety data sheets and you need to know the proper way to handle all the chemicals.

Frequently the supplier will tell you that a chemical has a certain function. But when you read the Material Safety Data Sheet (MSDS) and the proper way to handle the chemicals, you might find that there is a carcinogenic material in it!

Another huge issue to watch out for: the flash point might be very low (i.e. it is easy to catch on fire).

Yet another issue – some of the solvents are not compatible to what you are doing, or they are not allowed by the government in certain regions.

While the specification sheet the company gives you will tell you about its manufacturing capabilities, the MSDS sheet pretty much tells you everything that is in the chemical.

Our COO, David Collins, remembers many cases where a Chinese supplier did not fill out the MSDS sheet. If that is true, it is a red flag. That supplier might simply be trying to protect its ‘trade secrets’ – but in the West this attitude is is not tolerated. Or they might be hiding certain things they don’t want you to see.

3. Any permit required for some of the processes?

If a permit is necessary (e.g. for powder coating), ask to see it. Even if they do a nice job capturing all the pollutants, they might get closed right away by government inspectors if they have never been granted a permit to perform that process.

In addition, make sure the permit is for the address of the facility where the operations are being carried out. It is not uncommon for a supplier to show a permit for another building (which they might also exploit), and that is NOT a legal permit. Moving the entire operation to the right building might take months, and they would have to stop production in the meantime…

4. Is the city actively driving the activities away?

A lawyer or a chamber of commerce can also look into the dangers associated specifically with the area where each major process is performed.

Some cities are less welcoming than others to certain operations and have seriously increased anti-pollution inspections. Here are a few examples:

- Shenzhen and Dongguan actively drive anodizing and painting operations away. Don’t try to get a new permit for carrying out one of these processes.

- The same thing is happening in Shandong with air permits for die-casting.

(Differences from city to city are not new. PCB manufacturers have been more welcome in Huizhou than in Dongguan for years.)

Once you have collected information (or seen your requests for information turned down), the next step is to decide whether you should start working with your current suppliers on solutions, or start qualifying and developing some backup manufacturers.

This is what we’ll cover in our third article on this topic.

Has your business been affected recently by anti-pollution inspection in China? How so?

What was the solution, or are you still struggling to find one?

Does pollution in China affect you? Let us know your experiences or difficulties as a comment, we'll try to help you by responding.