When Chinese factories struggle to fulfil customer orders on time, we see many of them consider investing in increasing capacity without analyzing what keeps their products from reaching customers properly in the first place.

Problems could lie in something as simple as a job station, machine, testing, or supplier. You might also find that your planning, finance systems, warehouses and customers can affect production and delivery.

How do you analyze the actual vs potential capacity of your processes? How do you find out what needs to be fixed? When identifying production bottlenecks and managing them, you often start the first phase of your plant turnaround. In this article, we'll explain how to do that.

What is a Production Bottleneck?

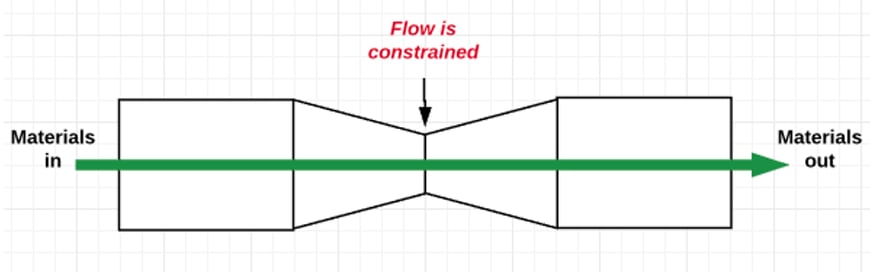

A production bottleneck is something that limits the capacity of a system. Just like the smaller neck of a bottle of wine prevents one from spilling all the bottle's contents in a few seconds should it be knocked over by accident.

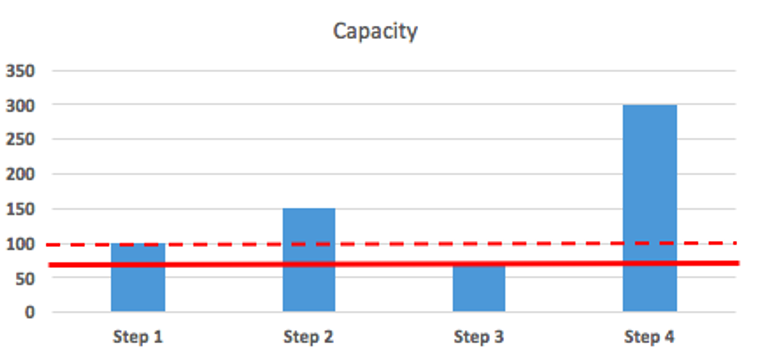

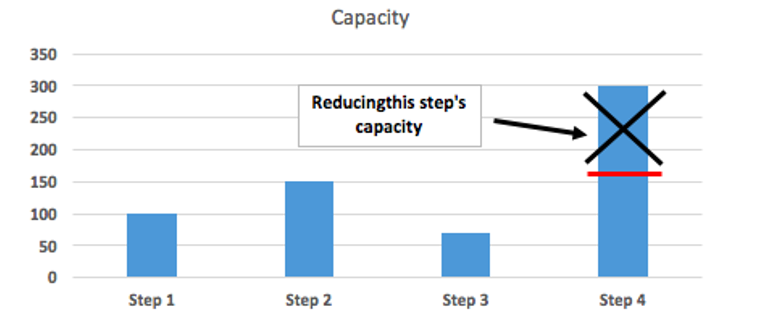

Let's look at this another way. You might have 4 steps in a process. In the next example, step 3 is the bottleneck (with a capacity of only 70), as indicated by the continuous red line. It constrains the whole process' capacity:

If you elevate its capacity to 90, the whole process output can go up to 90, and at that point, there are 2 bottlenecks: step 1 and step 3 (see the dashed red line below). In other words, by elevating that step's capacity by 29%, you boost the entire process' capacity by 29%.

What are the Impacts of Production Bottlenecks?

-

Shrinks overall production capacity: Production bottlenecks can significantly reduce your manufacturing process' capacity, leading to late deliveries and unhappy customers.

-

Creates excess inventory: Excess work-in-progress inventory tends to accumulate before the bottleneck, leading to increased storage costs and tied-up capital.

-

Strains employees and equipment: Bottlenecks can put substantial strain on both your workforce and machinery, resulting in more errors, decreased morale, and faster equipment wear-and-tear.

-

Impacts profits negatively: Bottlenecks can considerably eat into your profits due to increased operational expenses, lost sales, and the possibility of customer attrition.

How to Remove Bottlenecks in Production

Step 1: Find & Identify Production Bottlenecks in Production

If the production bottleneck is not the first operation in a series of operations, a lot of inventory tends to be waiting before the bottleneck. For example, in one study, the value stream map revealed that 30 days of stock were waiting before CNC machining, and another 45 days were waiting before assembly: these were the 2 bottlenecks in that factory.

A more scientific approach is to make a bar chart, as shown in the previous section. It is one of the most common lean methods and tools used to calculate how balanced (or imbalanced) a process is.

| Note: Make sure to calculate the capacity per process step, not per person or machine (since more than one person/machine might be part of a process step). Break the process down into stages that make sense. Junior industrial engineers know how to do this. |

Bottlenecking Because of Customers

Customers can become bottlenecks in several ways. They can happen with the customer changing engineering on you once the order is placed or if they direct parts, it can be slow with part shipping. Your customer can also be the bottleneck due to poor planning on their end. They send orders and, throughout the period when you are supposed to produce, they make many changes. These changes can make you change tooling, have the wrong materials set up for the line, or create problems if the complexity of one product is too great and you need a good mix to keep the line running correctly.

In this case, managing your customer is essential. You can do the planning for the month and fix up the planning to control the workflow. This is often necessary. You will be fine by the end of the month, but you may not meet the daily plan.

Bottlenecking Because of Equipment

Equipment maintenance is also important. We have discussed maintenance many times in our articles, but your most significant bottleneck will come up when your machines are not operational when needed.

Preventative and predictive maintenance will be your most significant help to keep your equipment running. Setting up these programs will be a must. Having well-trained people to manage this is the most critical part of the process. These people will be worth the extra pay. They will keep your factory running and make sure that you stay working.

Bottlenecking Because of the Supply Chain

Your product may be made up of 20 different parts coming from 15 other suppliers. If one of these suppliers can't deliver parts per your schedule, they hold you back.

Ideally, you'd have backup suppliers for each part. It is not tricky for standard parts but much more time-consuming for custom parts.

And it might not be feasible at all for you if you are in the same situation as the typical car manufacturer (switching to 1 new factory for 1 part triggers costly safety testing and approvals). In that case, a solid risk analysis upfront is a must.

Step 2: Reduce the Impact of Bottlenecks in Production

Now that you see the production bottlenecks, what should you do? Bottlenecks are not necessarily evil, as explained by Eli Goldratt in The Goal. And they can't be avoided (there will always be at least one bottleneck). But one has to plan around the bottleneck(s).

3 Management Approaches to Address Capacity-based Bottlenecks:

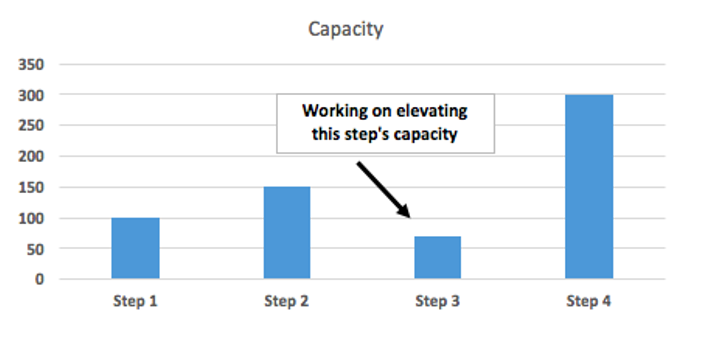

1. Elevate the Capacity of Bottleneck Operations

There are several options to achieve this goal:

- Process improvement – for example, studying the OEE components for a piece of equipment and improving the ratios.

- Adding capacity by increasing resources (workers, machines) is often done best with inexpensive, low-tech, low-complexity equipment that will be done less frequently than a complex, high-tech solution.

- Adding capacity by automating the process further – we always advise carefully assessing the benefits of full automation and going slowly in that direction (let your staff become familiar with automation and how to maintain it).

- Subcontract work to other companies when needed. However, it may pose issues in terms of quality and confidentiality, but you cannot neglect the economic benefits to your factory if your demand is uneven/seasonal.

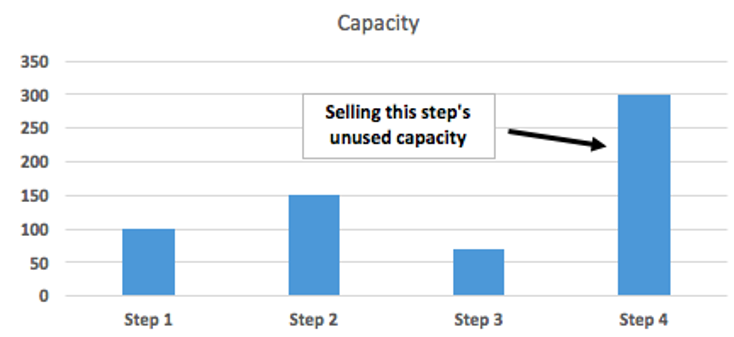

2. Sell the Extra, Unused Capacity of Other, Non-Bottlenecked Processes

For example, if you have 20 injection presses but only use 12 of them, you might want to find other companies interested in subcontracting some injection molding work. You will make money if you charge more than your variable costs.

3. Downsize Unused Capacity

For example, you can sell the 8 injection presses that are unnecessary for its operations and lay off / displace the operators and technicians taking care of those 8 presses.

Final Thoughts on Managing Production Bottlenecks

The concept of bottlenecking was central to the Theory of Constraints. It is paramount to Lean Manufacturing's Just-In-Time pillar but is not explicitly mentioned as such. As noted above, a simple bar chart based on a work breakdown sheet is usually the most adapted tool. A value stream map can help too.

Have you worked on your operations’ bottlenecks? Have you met success? Maybe you can share some observations with our community in the comments below?