There are various signs to consider relocating your manufacturing plant. Whether you're in consideration to reshore your manufacturing plant, or moving to an entirely new continent, establishing a solid factory relocation plan is crucial.

Considerations and Advantages to Plant Relocation

With multiple interconnected moving parts, your organization needs to have the ability to manage the hiring and training of new staff, comply with location-specific import/export regulations, and update or renew equipment simultaneously among other essential tasks. Delays, setbacks, and unforeseeable problems are commonplace with such large-scale multicomponent operations.

Despite potential pitfalls and challenges to plant relocation, plant relocation can present numerous advantages — lower labor costs, tax benefits, government incentive programs, improvement processes with minimal disruption, and access to new markets, among others. These advantages can make the whole endeavour worth all the time, expense, and effort.

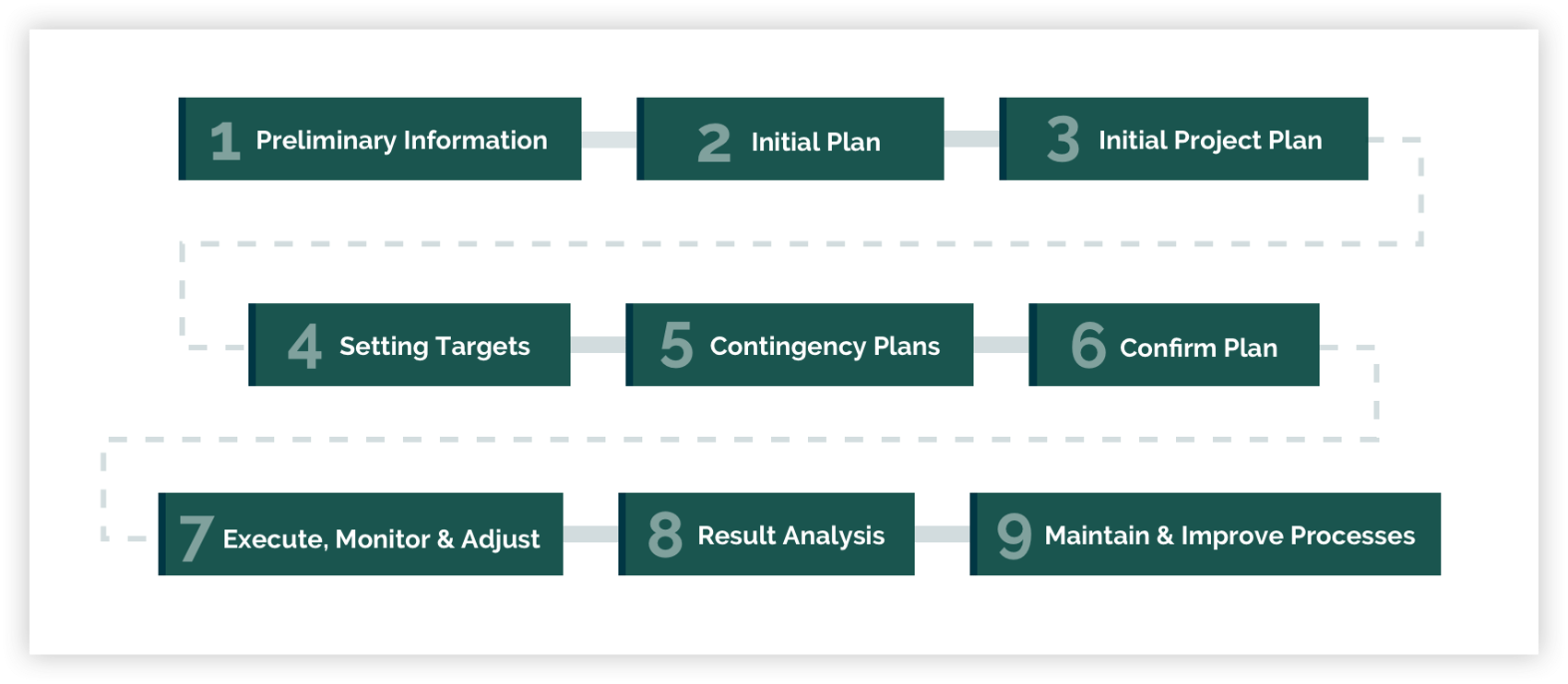

9 Steps for a Successful Manufacturing Plant Relocation

To help you make this process as smooth and easy as possible, we have put together a comprehensive 9-part blog series, so you and your organization can understand its needs. With this, you can plan an appropriate production layout, implement changes, and get started with production.

Our guide applies to all organizations, whether you are a simple 10-person shop or a multi-million dollar facility employing hundreds of people — the same principles apply, only the scale and complexity change.

The 9 Steps for a Successful Manufacturing Plant Relocation

1. Preliminary Information

2. Initial Plan

3. Initial Project Plan

4. Setting Targets

5. Contingency Plan

6. Confirm Plan

7. Execute, Monitor & Adjust

8. Result Analysis

9. Maintain & Improve Processes

About The Author

With over 10 years of experience, CMC’s leaders have an in-depth understanding of what it takes to relocate a factory. Get insight into what it takes to move your facility in this series.

David Collins III, CMC’s founding partner, has had extensive experience setting up new factories of over 1 billion USD and consulting for numerous production facilities, including the assembly line for the F-35 jet. David also has a comprehensive understanding of the automotive industry, having built four factories that included robot installation, chemical processes, assembly, welding, electronics, setting up the maintenance systems and process controls, and most importantly staff training and hiring.

Over the series, we will discuss the questions you should ask, and the steps you need to take to ensure that factory relocation is smooth, timely, and cost-effective. For updates when we release each part, subscribe to our China Manufacturing Improvement Blog.

CMC is committed to providing you with the latest quality content and insights, download our FREE guide to plant relocation now.