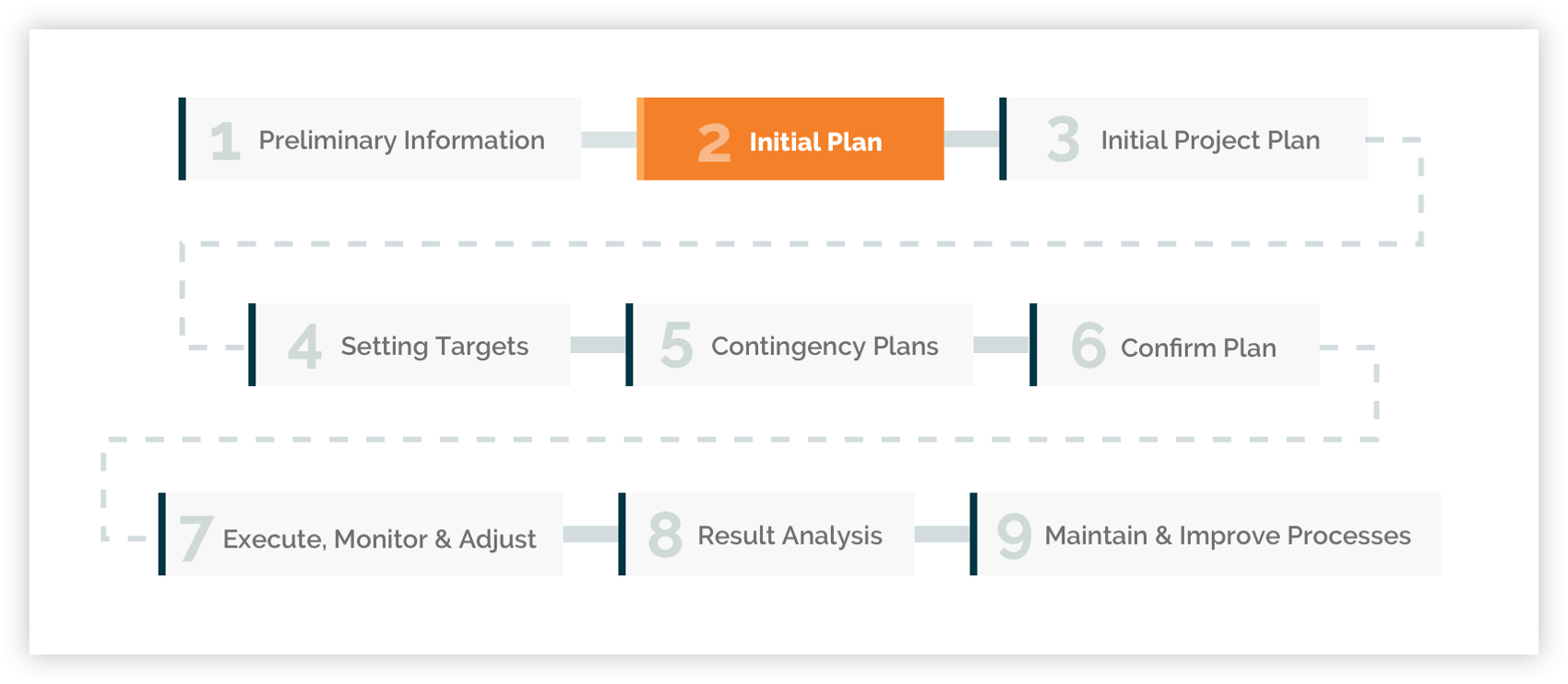

This is the 2nd part of "9 Steps to Successful Plant Relocation". If you'd like to view other posts in the series, the links are available on the right side menu of this post (desktop) or at the end (mobile).

Once you have collected sufficient data regarding the size, scope, and potential needs of your new manufacturing facility, you can begin defining your initial plan.

How to Create an Initial Plan for Plant Relocation

The information gathered in the first step will help you and your team understand the framework and constraints that you may have to contend with over the course of the facility relocation project.

It is important to remember that the main aim of an initial plan is not only to help determine the relocation action plan but also to anticipate unforeseen circumstances. This is not to say that there won’t be unforeseen circumstances (because there usually will be), but you will be prepared for most of the “known unknowns.”

2 Important Questions to Consider

Armed with all the preliminary information, the initial planning will need to address two of the biggest questions:

- Has the site been selected?

- Does one need to be identified and evaluated?

It may be surprising, but the team in charge of the relocation may not have much input regarding the site location. If the new site has already been chosen, then you can move onto the next question. However, if it hasn’t been decided yet, you must develop criteria for an acceptable location based on the preliminary data gathered in the previous step.

The process of finding the correct location is often not as straightforward as it might seem. Though you are armed with all the information and understandings from the first step, reality will likely be different, and the value placed on certain considerations may change. For example, you assumed your site needed to be in a certain location, but upon closer inspection the labor rate or tax situation there is not advantageous.

Site selection with CMC

We recently conducted a site selection for one of our clients that wanted to evaluate multiple data points for each possible location. The system we developed gave each feature a different weight according to its importance.

Since our client needed to transport large equipment and products, a water transportation system along rivers or canals was essential to their operations. Our models and weighting systems were adapted as the client better understood its needs through the process.

While having a location already picked out can save time, finding a location can give your company a great deal of insight into the capabilities of the new factory and help you develop a better understanding of your needs.

Will it be necessary to construct a new building?

Similar to site selection, constructing a new building or using an existing building each present their own advantages and disadvantages.

Using an existing building is usually cheaper and quicker to get operational than a new build. Most countries and regions also have the industrial capacity to alter the building to match your company’s needs. On the other hand, a new building allows your company to design it according to your specific needs. A modular design gives you the flexibility to expand as needed with simple-to-add segments. At CMC, we often advise our clients to use a modular design, especially if they are unsure of their production needs in the future.

The bottom line

When developing your initial plan for plant relocation, you should be both careful and thorough. While most companies only think about their old location and replicating it at the new site, moving is actually a great opportunity to make changes that improve your layout while reducing costs.

To do so, you will need to think about materials going both in and out of the facility, and its distance to the warehouse. This will also help inform your understanding of what is required from the design to create the optimal flow of the product, from raw material to finished goods.

As you answer the questions above, you and your team will be able to begin planning the factory layout, start sketching out a timeline and come up with an initial project plan—which we will discuss next.

CMC is committed to providing you with the latest quality content and insights, download our FREE guide to plant relocation now.