Founded in 2012, CMC includes a team of more than 20 full-time manufacturing consultants, with backgrounds in a wide range of manufacturing types, including, but not limited to, automotive, electronics, textiles, industrial machinery, and furniture.

We are manufacturing people through and through, and have worked with both Western and Chinese factories throughout our careers - working on the factory floor and in the executive suites to fix issues as they are happening.

Read About Us

CMC's manufacturing consultants have experience of working in the majority of manufacturing fields, but we have a particularly strong focus on:

Tiers 1 & 2

(including on-site paint shops)

Our firm includes the competencies necessary for driving the most common types of improvement projects in a manufacturing company. We support clients in the following areas:

Cut your costs thanks to lean manufacturing tools and preventative maintenance, and engage the workforce to make it sustainable.

Fix processes and organization with strong support from technical & management specialists, and then work toward excellence.

Apply statistical process control and mistake-proofing where they make sense, set up a strong quality system, and train staff properly.

Follow the right steps to get to production launch in great conditions. Good project management, from site choice to process layout.

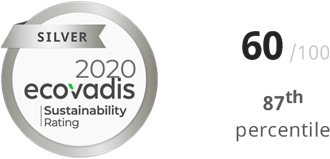

CMC is committed to being an advocate in the field of sustainability within the manufacturing industry. Our commitment to sustainability has been recognised by the leading business sustainability rating agency, Ecovadis.

Expand your business operations, save money, and learn about some of the most recent manufacturing news and technologies from our blog posts.