This is the 3rd part of "9 Steps to Successful Plant Relocation". If you'd like to view other posts in the series, the links are available on the right side menu of this post (desktop) or at the end (mobile).

At this stage, an initial project plan for construction (for a new plant) or modification (for an existing location) up to full production can be created. The project plan should have reasonable expectations on the time necessary for each phase, responsibility for the parts, and the necessary components (labor, equipment, etc.).

Creating an Initial Project Plan for Factory Relocation

The project plan is key to ordering operations and understanding what needs to come first and what activities can be undertaken at the same time. For example, it is possible to start training employees as the machinery comes in rather than waiting for the full delivery and set up all the machinery.

For this reason, we recommend the modular approach as mentioned in the previous step. Modular step allows for each module to be completed semi-independently of other modules for better control of each module and to start production before the facility is 100% complete. Doing so saves both time and money.

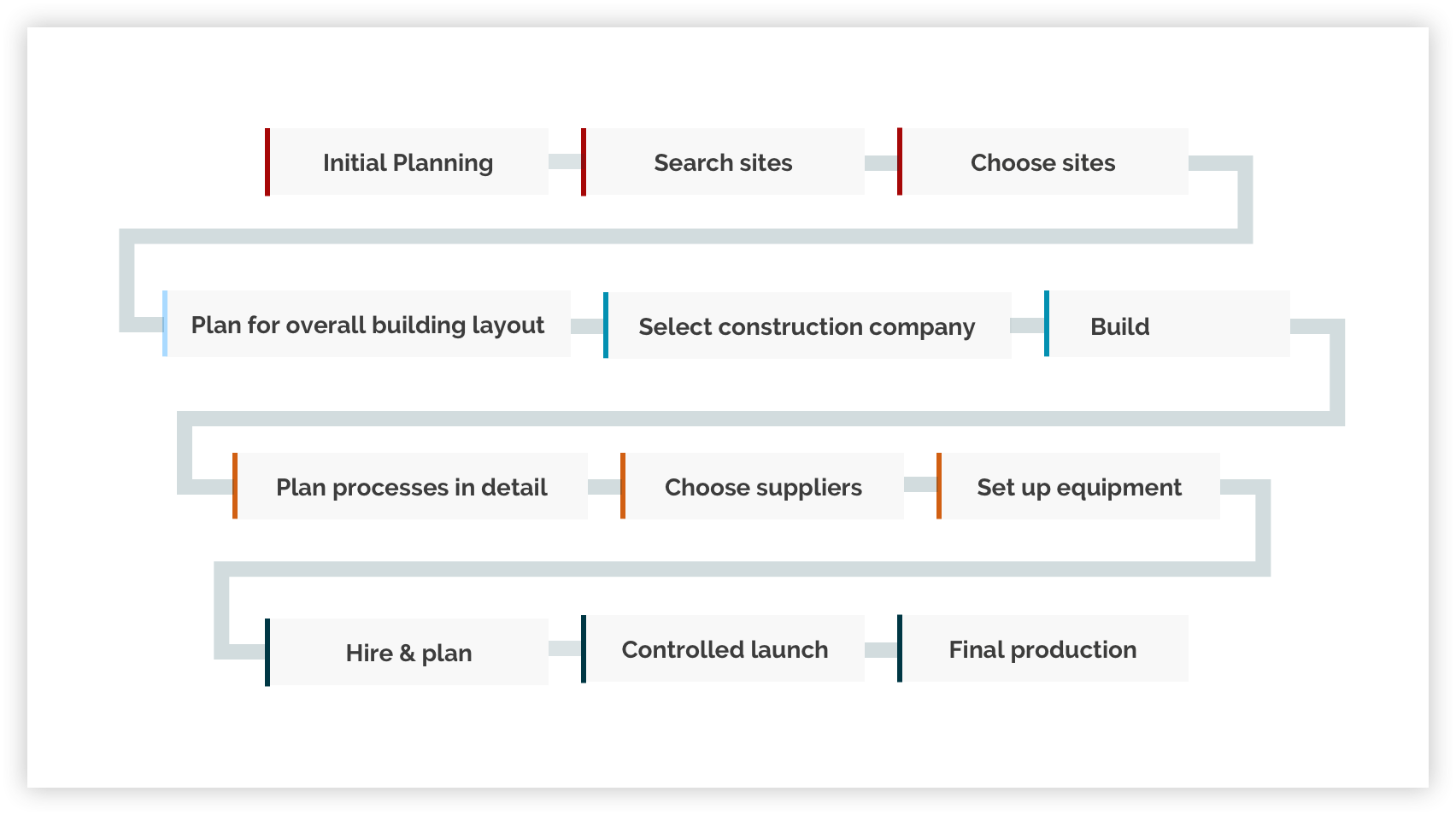

There are obviously more steps to follow in case of a "greenfield facility” (a brand-new facility that has to be built from scratch), than when using an existing building.

Why the Typical New Factory Setup Plan Needs Improvement

Without a modular structure, a typical high-level overview of a (greenfield) new factory setup project looks like this:

(For an existing building, you would be able to remove “select construction company” and “build Modules” but the general concepts remain the same.)

This already looks like a well-thought-out project and is the traditional approach we have seen many times.

However, there are ways to start using and refining the processes earlier (this includes the equipment setup and maintenance, the methods and training of the people, and so on). If you can start producing earlier, even if that’s not at full capacity, you may be able to close the previous plant 3 months earlier, thus generating enormous savings.

How to do this? Here is what has become relatively common in the automotive industry.

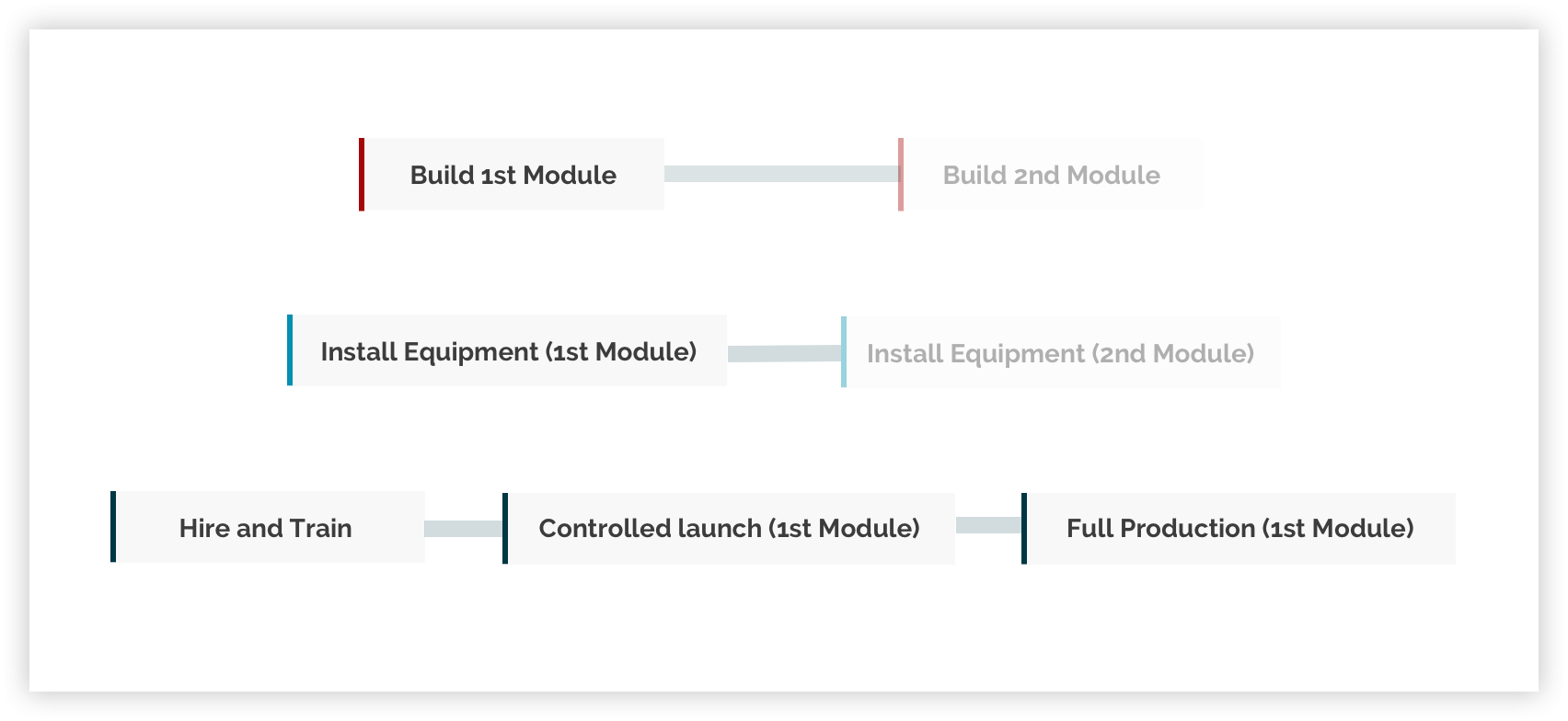

In many cases, production can start before the whole building is ready. Construction can proceed module by module. When the first module is ready, equipment can be installed, employees can be trained, and production can start.

Using a Modular Setup to Expand Your Plant

A modular setup makes it easy to expand the plant over time. This approach is seldom used in Asia but is generally faster and most cost-effective if planned correctly.

Below, we have an example of modular approach. This can be used for as many modules as needed, provided that each step is planned out beforehand.

Complexity of the project can vary greatly since building an airplane involves many more parts and considerably more precision that manufacturing rubber bath toys or sewing t-shirts.

However, the principle remains the same regardless of the production: plan carefully, set up equipment, train people and begin production. The location is also not important: the same template works in the most advanced manufacturing countries and the newly developing.

The modular approach makes optimal use of LEAN since each rollout is devised to ensure the production of the minimum viable product at that stage. For example, if you know that a certain piece is a major seller, that the module to produce that piece could be up and running while construction continues for another module for a product with a lower demand. It also gives flexibility for later scalability for larger or small production runs down the line.

Final Thoughts

CMC used this method to develop PPE factories for clients in response to the COVID-19 outbreak. Each line was an individual module and started production quickly to respond to the rapid demand with additional modules ready to install if demand required it. Utilizing this method, our clients had the flexibility to add or not add production in response to the market demands and to protect themselves from investing too much.

CMC is committed to providing you with the latest quality content and insights, download our FREE guide to plant relocation now.