The success of lean, one-piece flow, and mistake-proofing depend on long-term commitments. While many factories introduce process improvements, they fail to keep at it 90% of the time, often reverting to old processes within six months. Reverting to previous ways of working happens not due to a lack of commitment but because any significant process change needs an equally important shift in mindset.

A good analogy is a New Year’s Resolution. You go into the New Year with clear goals and determination. However, when you don’t see immediate results, you quickly feel less motivated to stick to your resolutions. Manufacturing consultants use the change management process to ensure your process improvements become a permanent part of your operations even after the consultants leave.

What Is a Change Management Consultant?

A change management consultant is in charge of introducing new ideas within a business and aiding in transforming how the organization runs. Two of a change management consultant's significant responsibilities are recognizing the areas where change is necessary and determining how it will impact the organization. So how do change management consultants, also known as organizational change consultants, ensure that changes stick?

4 Crucial Factors for Successful Change Management Consulting

A fair process ensures that the managers, supervisors, team leaders, and operators buy into changes. Here are two essential steps that organizational change consultants need to take to ensure cooperation.

1. Gets the Teams Input

Manufacturing consultants rarely know your business better than you or your operators, and they know process improvement, not necessarily individual companies. Operators and supervisors often have the most significant knowledge of what is hurting production and, if given the opportunity, can find innovative ways to fix the problem.

We have worked in concert with companies to develop teams of operators that take the lessons they have learned and continuously find innovative, new ways to improve their operations.

2. Makes Sure Everyone Understands the Changes

Change is not effective when given directives from the top. Manufacturing consultants are skilled at teaching and guiding employees to see what needs to be changed and why from the ground up. People work harder and make the change if they are active participants rather than passive observers—a clear understanding of why and how a process changes will lead to organizational buy-in.

3. Develop Your Employees

Change can be considered a challenge for many employees. Developing your employees will enable them to be prepared for future challenges. They will be more open to what other companies do and will grasp new concepts faster. If your employees have been following the same processes for many years, it could be necessary to implement some developmental measures.

4. Follow Robust Management Systems

In some factories, top management has put a system in place to ensure the leadership team works to the same objectives, which trickles down the organization. All parties tend to row in the same direction when a direction is approved. Each team usually has a few Key Performance Indicators (KPIs). In many other companies, the manager has to push the critical initiatives because nobody else will personally.

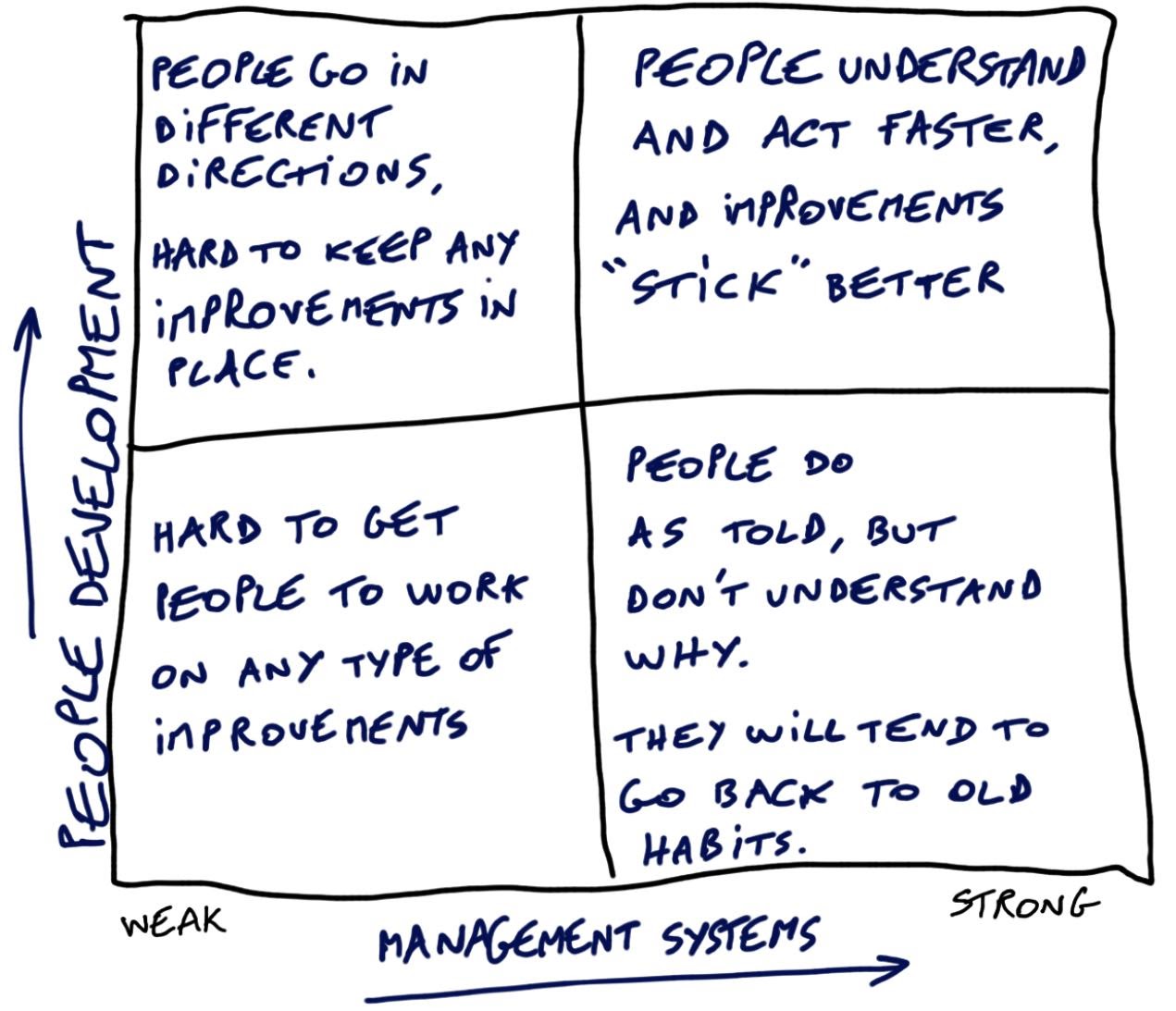

As you can see from the graph below, change is more likely to stick if there is strong people development and robust management systems. If one is weak, the other leads to inferior outcomes. Factory operations, like most organizations, need a formidable mix of freedom and direction to be successful.

Should You Invest in Change Management Consulting Services?

Failure to successfully follow through with change creates several drawbacks that make the situation worse. There is likely a loss of productivity from a poorly implemented change plan both on the front end, the immediate changes, and the back end when the changes start to break down. Worst yet, the experience is likely to make the manufacturing team more resistant to change in the future, making necessary improvements more challenging to implement.

Manufacturing consultants can help smooth the transition process, and help changes stick. Consultants are experts at change management and can gradually lead the company with more operator buy-in. Understanding how companies and individuals internalize changes can significantly differentiate between a passing attempt at change and real change.

Do you have any interesting experiences of implementing change at your factory? We would love to hear from you in the comments section.

Having trouble making changes stick? Want to learn these concepts in a more practical way?

Take a look at our case study to see how we've helped one of our clients to make an impactful and long-term improvement.