A very common issue for metal machining shops is dimensions out of specifications. And it comes down to poor dimensional control. It is quite common in China and creates all sorts of issues – quality of course, but also lower productivity (e.g. assembly is much harder).

1. Where does this problem come from?

There are a number of different reasons for dimensions to vary, some of which are:

- The machines which perform operations on the workpiece may have inherent inaccuracies built into them.

- The tools used on the machines are subject to dulling, general wear, chipping, breaking and differences occur due to replacement or regrinding.

- The material used for each part is subject to slight variations.

- Poor maintenance plan on machines (machines do not have a scheduled preventative maintenance plan).

- Incorrect cutting fluid causing localized cutting issues.

- The involvement of measure equipment/tool/gage/equipment.

In the vast majority of Chinese factories we have worked with, the biggest cause of variation in dimensions has been through lack of maintenance on machines which results in the machines inability to actually hold tight tolerances.

What Dimensions to Check

It is important when generating your 2D technical drawings that you understand the dimensioning format and the tolerances involved as well as what dimensions are critical and those that are not.

If you release production drawings with generic tolerance bands throughout the product and with no critical dimensions, and if the part is to be assembled to another part, at some point you will have issues with either the fit or the function of the part or assembly.

If you tighten up all your dimensions to a very narrow tolerance band then you may see an increased with quality issues and more rejected parts as well as increase in part cost.

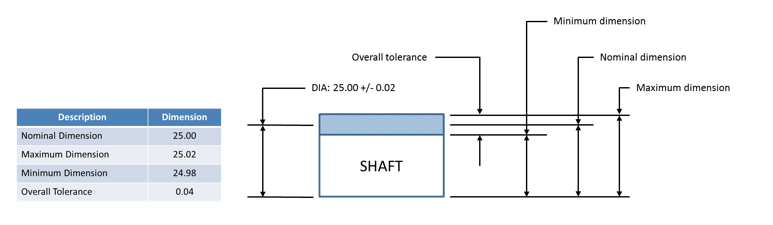

Below is a simple example of what a tolerance looks like.

If you do not understand the fit of each of the components and have not applied a tolerance to each of those areas, it will cause you problems when it comes to production.

It is common practice, and we have seen plenty of evidence of this, for machine shops to apply a ‘standard tolerance’ of the following: whole number dimensions ± 1.0, one decimal place dimensions ± 0.5, two decimal place dimensions ± 0.15, and angles ± 0.5°. This is especially the case where the supplier does not understand the design intent. If this causes you issues with fit form or function, be assured it will also cause you issues with delays and additional costs.

Wrong Material

Material selection is a crucial part of the design process and you need to start with understanding the functionality of the product.

Selecting the wrong material can result in poorly finished components as some materials are more difficult to machine than others. With difficult-to-machine materials, repeatability in achieving the correct dimensions can result in high reject rates during the machining process, or poor parts reaching your production line.

2. What are the Best Practices for Dimensional Control?

We usually propose the following ‘best practices’ to our clients:

1. Understand the Customer’s Requirements

By understanding all the key elements of the product, engineers will be able to specify every point in fine detail. One of the easiest ways to get the details recorded down is to carry out the 5 W’s and one H analysis on each part and assembly.

- Who?

Who is going to use the product? This could start off with the first person in the chain AFTER production of a single part, working right through to the end user and ultimately to the recycling stage.

Some of these answers will trigger further actions, for example, “who is the product intended for?”, if you answer is babies, then you may have to look into safety regulations and material restrictions.

Ask ‘who’ and have answers for each question until there is no more ‘who’ questions left to answer.

- What?

What is this part used for? What is the function of this part? What are the mechanical properties needed? What are the cosmetic properties needed?

As you can see from these examples, asking ‘what’ will drive you to answer each of the questions and at the same time you are building up your product knowledge and specification.

- Where?

By asking ‘where’ in a number of different contexts you will be able to determine elements of the product specification such as, is weather resistance needed, is it an indoor or outdoor product which could require different materials or finishes, environmental issues come into play as well temperature the product is to operate in.

- When?

Is the product to be used constantly, 27/7 365 days of the year or intermittently? Is the part to be used at night time or daytime only, on holidays, during a particular time and function of a mechanical cycle? All these questions will provide yet more information with respect to building the product specification.

- Why?

Here you can ask questions like why does this dimension need a tight tolerance, or why is a specific part designed to a specific shape. Even why something is needed at all or why is there two individual parts instead of one.

By providing answers to as many ‘why’ questions you can think of will allow you to optimize your design and ultimately your product specification.

- How?

The additional H question is the ‘how’, this provides the opportunity of reviewing how the product will be made, how the product functions, how the parts interact, how one part is affected but another. Ensure you cover as many as you can think of and provide the best possible answers.

2. Product Analysis and Specification

After completing the 5 W’s and 1 H analysis you should be in a position where you understand your product to a greater depth of knowledge. The documentation generated during this analysis would be a good starting point of a good technical specification.

From the specification, you should now be able to specify the correct material, generate detailed technical 2D drawings showing the correct dimensions and the appropriate tolerance as well having the product optimized for manufacture, assembly, and final use.

Having a specification that has been generated through analysis will provide the right information to allow your product to be manufactured with reliable stable dimensions.

3. Best Machine for the Job

Once the product has been fully defined and optimized and manufacturing details have been generated, the next process is to get your parts machined.

Depending upon the shape, specification and geometry of each part will determine what machining process is required, for example: Turning, Milling, Drilling, or Grinding.

These are individual operations and carried out by dedicated machines. A more advanced and repeatable machining process would be the use of CNC machines and CNC Machining Centres.

4. Correct Tolerances for the fit of Hole and Shaft

This hole and shaft Tolerancing is covered by the ISO System of Limits and Fits which is a coordinated system of hole and shaft tolerances for engineering and manufacturing. The limits are defined as the extreme values of the dimensions and the fit is defined as the degree of tightness or looseness between two mating parts that are intended to fit together.

There are four types of fit between parts, and we won’t get in this level of detail in this article.

- Clearance Fit

- Interference Fit

- Transition Fit

- Line Fit

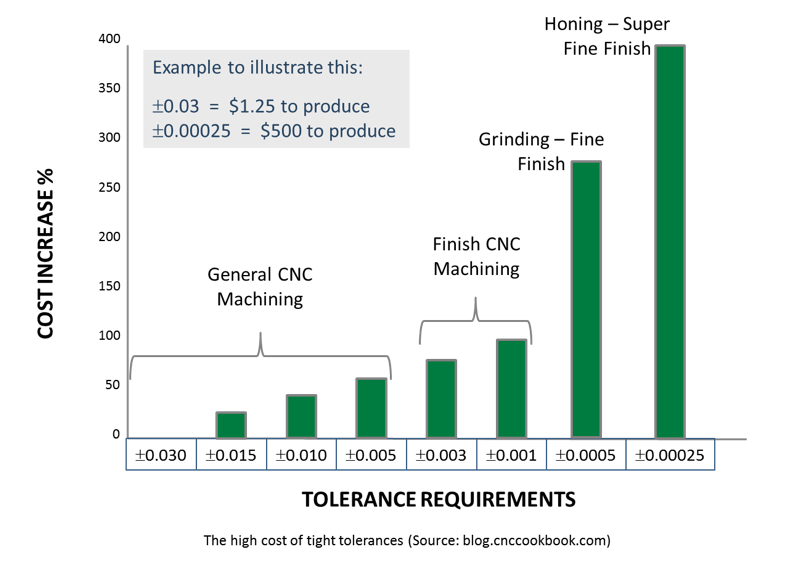

5. Tolerance vs Cost

When it comes to selecting the right tolerances for your part, it is important you understand the correlation between a tight tolerance and the cost to achieve that tolerance.

The table below shows there is a large discrepancy between a general tolerance and a super tight tolerance; in fact, it will cost you four hundred times more to achieve a tolerance of ±0.00025 inch than it would of ±0.03 inch. This is because of the machining processes required for the different accuracies.

Make sure you also understand the capabilities of your manufacturing partner and what their machining processes can achieve.

Is this consistent with what you have been doing (or not doing)? Do you have any extra tips to complement the advice contained in this article? Leave a comment below, we'd love to connect with you!