US Manufacturing Consultants

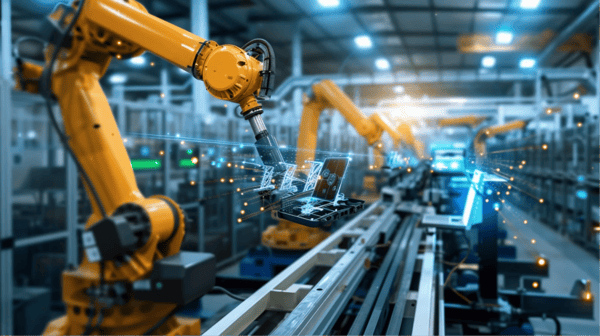

Improve Your Manufacturing Operations in the US

Partner with our 'boots on the ground' experts to refine operations, reduce inventory, and cut costs in your facilities in the US.

We bring actionable insights right to your factory floor.

Experienced Factory Management & Technical Consultants Based in America

Our consultants are seasoned manufacturing veterans, adept in improving both Western and international factory operations. Working directly at your facilities, we tackle immediate challenges and strategize long-term advancements from the production line to the executive boardroom.

Our Manufacturing Consultancy Services

Assessments and observations help us form the basis for our consulting services. We conduct in-depth evaluations of your processes, management, and layouts, moving beyond basic audits to identify fundamental issues.

Our focus is on sustainable improvement, not just temporary fixes.

MTG's specialists have successfully improved manufacturing outcomes (lower costs, faster delivery, higher quality) across a wide variety of industries and locations.

Our proven approach using lean manufacturing, six sigma, and decades of experience will achieve the quickest results for your factories in America.

We excel in revitalizing factory operations across North America. Our boots-on-the-ground consultants bring local insights and hands-on expertise to tackle your factory's unique challenges.

We focus on identifying and solving issues, enhancing performance, and driving continuous improvement.

Moving production to a new location can often involve risks, costs, and decisions about resources, strategy, technology, and people. Working with MTG consultants can make this transition far smoother, allowing businesses to maximize their nearshoring or reshoring efforts.

Our reshoring services encompass everything from pre-relocation planning and site selection to process development, offering end-to-end manufacturing consulting up to the launch of your factory.

Where We Help You On-Site

Process Control

We focus on improving productivity at your facility and preventing human error, with tools like line rebalancing, poka-yoke, process improvement, and more.

Removing Bottlenecks

We use logistical and process changes, operator training, and self-inspection, among other tools, to achieve continuous flow production.

Quick Results

We aim to maximize benefit in a condensed timeframe by determining high impact improvements.

Standardized Workflow

We help companies analyze their entire workflow to identify opportunities to improve efficiency by implementing standard operating procedures and training staff for sustained improvements.

Mistake Proofing

As ‘inventory’ and ‘defects’ are less detectable in technical processes, productivity can often be a significant issue. We help improve this through changes in logistics, mistake-proofing, and other tools.

Improved Productivity

We focus on developing a process improvement plan for a system with reduced cycle time and higher productivity by addressing procedural, data transparency, and cooperation issues.

Successful Manufacturing Transformation in the US

We typically work on engagements of 3-12 months with our consultants at your facility several days a week. Our engagement managers provide guidance, and our technical consultants provide the type of assistance necessary to reach your objectives.

Increased Profits With Reduced Lead Time for an Industrial Transportation Manufacturer

4 years spread across

multiple KPI-focused projects

- Output increased from 1.1 units to 2.3 units, per line, per shift - increasing potential sales to $10 million annually.

- The production lead time was reduced from nine months to just one month.

Enhancing Production Efficiency For a US-Based Window Manufacturer

4 Months

- Increased annual revenue by $2 million.

- Increased daily production value by $6,000+.

- Boosted OEE from 40% to 83%.

- Reduced headcount, achieved up to 40% improvement in production output.

- Improved cash flow by $50,000+ per month by reducing inventory and Work in Progress (WIP).