Over the years, I have visited hundreds of Chinese factories, but I rarely see good manufacturing work instructions at the disposal of production operators, maintenance technicians, and quality inspectors.

If your New Product Introduction (NPI) engineers haven’t prepared a standard work instruction sheet already, you’ll need to start writing them up. When writing your manufacturing procedures, you should follow the 6 principles outlined below to ensure that your instructions are easy to follow:

After gaining an understanding on the 6 principles of standard work instructions, dive deeper into the 3 standard work instruction examples you can learn from:

-

Standard Work Instruction Example 1: IKEA’s Instruction Manual for Furniture Assembly

-

Standard Work Instruction Example 2: Standard Operation Sheet

Standard Work Instructions: The 6 Principles

1. Standardize the Work

The core idea behind manufacturing instructions is to follow ‘one best way currently known in this organisation’ so that if 5 people work on a particular job, they do it in the same way. If every operator has their own processes, it can make improving the way they work quite difficult. By following the standard manufacturing processes, one improvement to the work instructions can be applied immediately across the board and increase productivity, quality, and safety.

Before you standardize the process, think of ways to simplify each step. It is a huge win if you can set up fixtures, gauges, and other tools to make the work easier to do. Don't delay it if you have the engineering resources to do that now!

2. Work With People in the Manufacturing Process to Create Standard Work Instructions

The people involved in the manufacturing process day in and day out often know how to do a better job than most engineers sitting in your office. They might not try to do a good job in certain instances. For example, when they are paid by the piece and never have to do rework on the mess they have made. But, usually, they know how to do it.

Why not pull them out of production for an hour and work together to determine the optimal manufacturing process? It not only gives you a better insight into the procedures, but it also trains them to think in a better way. And who knows, maybe they’ll keep thinking of it at the back of their mind, and in a week, they may think of a better process.

You should even involve the production line or group leaders to push them to think outside the box. Over time, they’ll learn how to solve problems too.

3. Get Employee Buy-In On Standard Work Instructions

Most Chinese factories treat their low-level employees as disposable resources. They tell them what to do, provide them with no training, and hope to replace them as fast as possible with automation. Don’t fall into that trap! Getting your employee’s feedback during the decision-making process can be a determining factor of your company’s success as it may also lead to higher employee engagement.

Involving the workers when writing work instructions leads to sustainable improvement as you get their buy-in. Even if they disagree with an aspect of it, you’ll give them the opportunity to share their opinion and discuss it with their teams. In the end, they might still be unhappy, but it is better to have received their input, and it may lead to less resistance from them.

4. Visualize Standard Work Instructions

Once work instructions are written up, they need to be enforced. A leader or supervisor needs to be able to walk around and identify at a quick glance if the standards are being followed. Drawings can reflect the manufacturing instructions much better than text paragraphs.

I have seen many work instruction sheets written on bland templates with no graphic element to visualize the manufacturing process, and unsurprisingly, nobody reads them.

5. Include Other Elements

When people think of standard work instructions, they think of a work sequence – first do this, next do that, etc. Having this is quite useful, especially if it also includes material movement and transformation and inspection and testing activities.

But that’s not the only thing your manufacturing work instructions should encompass. Try to include a standard timing, i.e. how long is a particular process supposed to take to keep the line balanced. This shouldn’t be used to penalize workers or single out those who are too slow. Rather, it should put some healthy pressure and indicate who needs specialized training.

In lean organizations that try to get as close as possible to a one-piece flow, including the minimum and/or maximum number of pieces in the process at any given time is crucial.

Considering other points is crucial, too, like the importance of safety as well as quality.

6. Train Your Process Engineers

Do you want to develop your junior engineers? You can get them to work on projects to increase productivity based on the work instructions and other data they gather.

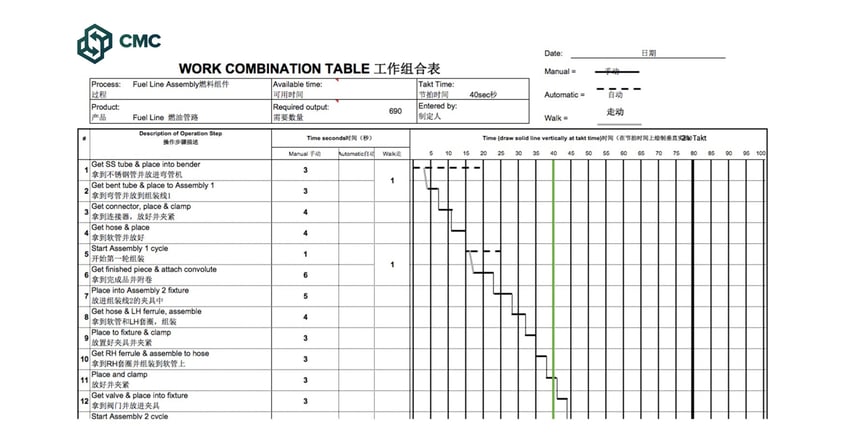

Developing a combination table is useful when you want to go deep into the details. It shows the details of manual cycle time, automatic cycle time, walking time, and waiting time for 1 operator. Here’s an example of a combination table with dummy data:

3 Standard Work Instruction Examples

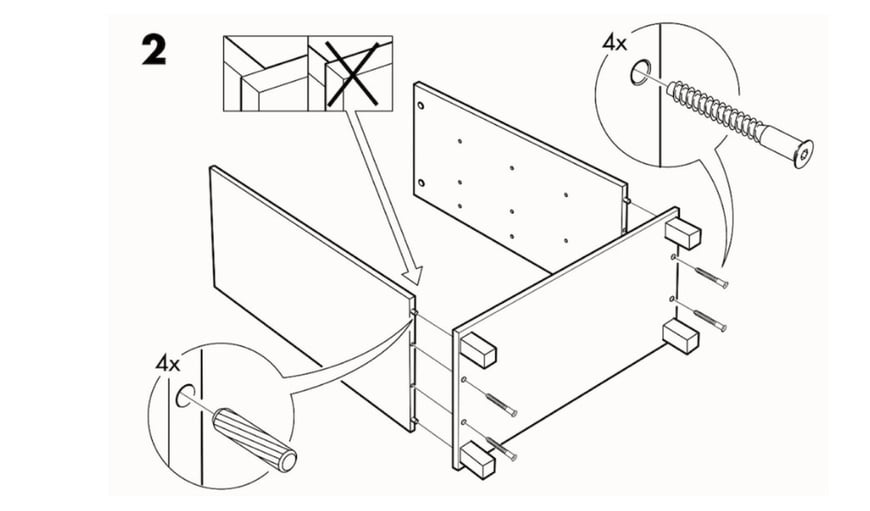

Standard Work Instruction Example 1: IKEA’s Instruction Manual for Furniture Assembly

Standard work instructions should be visual. Drawings, pictures, and even videos are much more likely to be followed by operators. IKEA’s furniture assembly instruction manual is a great example, as their manuals are easy to follow with clear visual instructions.

Note: IKEA also has other excellent examples on mistake-proofing.

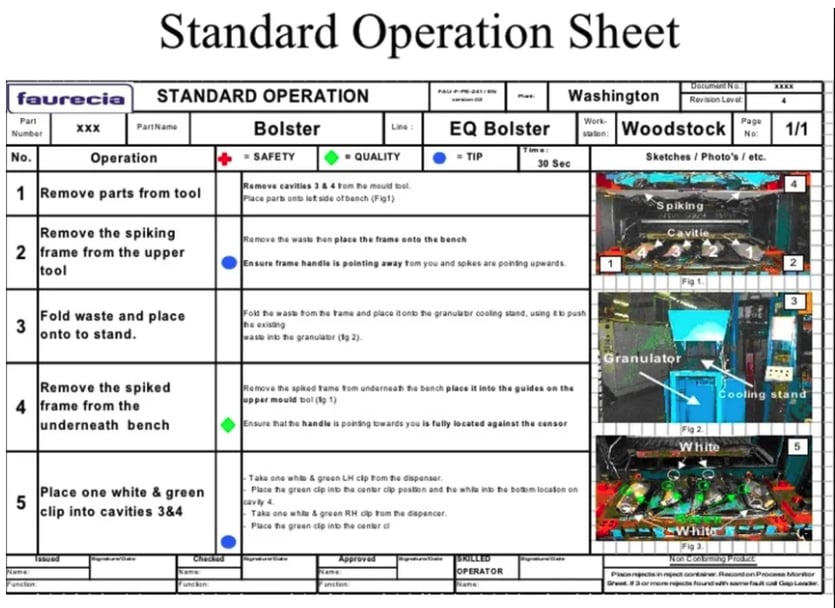

Standard Work Instruction Example 2: Standard Operation Sheet

The standard operation sheet is a document that outlines the step-by-step procedures and materials needed to complete a specific task or operation.

This standard operation sheet is clearly formatted, with operations laid out in specific steps. As with any other automotive supplier, the creation of this sheet involves production workers in creating these instructions, leveraging their hands-on knowledge to optimize procedures. Visuals are then applied, helping employees grasp the process. Your team may also want to implement symbols so that employees are drawn to key areas that require special attention.

Standard Work Instruction Example 3: Work Combination Table

Another standard work instruction example is a Work Combination Table. This table breaks down each step of the process into precise time segments. Here, a fuel line is being assembled. Manufacturing processes are split into steps, and time periods are allocated to each process. The Work Combination Table visualizes all the steps in the manufacturing process while giving users clear projections of the time for all the manufacturing steps.

The importance of standard work instructions in manufacturing cannot be overstated. They are essential tools for maintaining a high level of quality, safety, and efficiency in production processes. By providing a clear, standardized guide to performing tasks, these instructions help to reduce variations and errors, leading to a more reliable and efficient manufacturing process.

Have you had positive or negative experiences with writing work instructions? Do you see them as an essential element? Or are they merely a decoration for auditors and customers? Let us know in the comments below.

Looking to improve your manufacturing processes while cutting costs?

Download our complimentary eBook on 'How to Cut Costs in Your Factory Through Quality Improvement Activities' below: