Problems arise every day in factories. In a typical Chinese factory, in particular, managers and engineers spend their time “firefighting” rather than proactively solving issues before they happen.

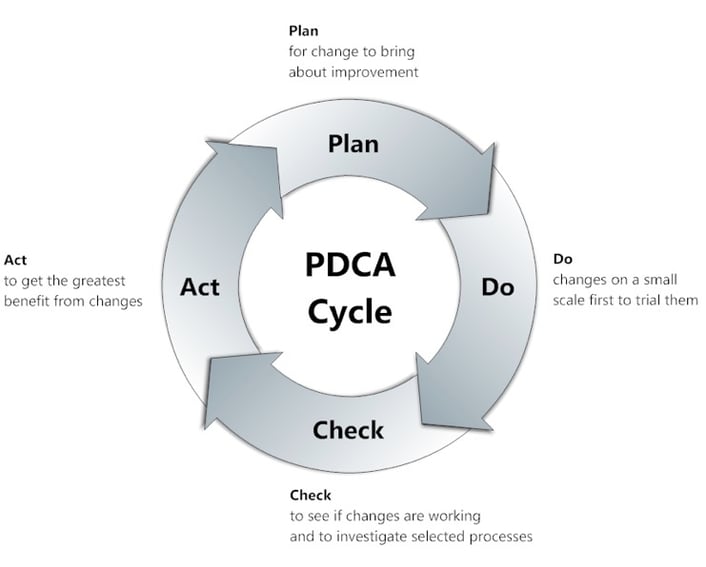

This can lead to despair, and being in a position where we ask: "How to fix my factory in China?"In this post, we'll take a look at how to fix a factory using Plan-Do-Check-Act (PDCA) method—an iterative four-step model for continuously improving processes, products and services in any organization.

Why PDCA is Important in China

Chinese engineers tend to adopt a shotgun approach to problem-solving, often remaining at the surface of issues without going down to solve root cause(s).

This is largely due to the fact that the education system doesn't aim develop analytical thinking. In China, knowing the answer is sufficient to pass the test: The WHY and the HOW are usually not needed. A scientific approach to problem resolution does not come naturally as a result.

To foster ideal working habits and ensure that all steps in procedures are followed, factories in China especially need a framework to stabilize quality. (Note that we’ll focus on corrective actions, not on corrections – for example, re-working defective products is not part of the effort at long-term improvement.)

PDCA vs. PDCA 2.0: Choosing a Framework that Works for Your Factory

Image courtesy of ASQ.org

The PDCA cycle is the basis for applying the scientific method (study, form theories, test theories, apply if confirmed or go back to an earlier step if not confirmed).

For small issues, PDCA is great. People are encouraged to observe, make a test, see if it works, and so on. Spending hours on following a certain method is a waste of time when it comes to small problems that need urgent attention. The faster the analysis and the corrective action are applied, the fewer products are affected by the quality issue!

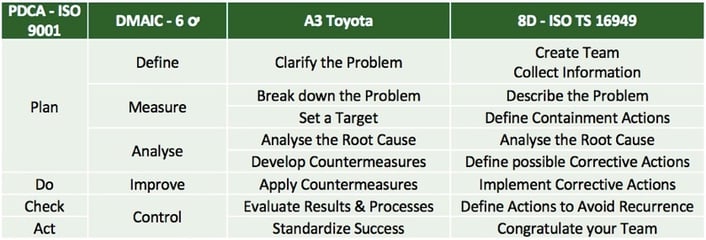

However, the PDCA cycle itself is not detailed enough to act as a guide for a serious, in-depth improvement project. Several other methodologies have emerged, among which:

- Toyota and the practical problem-solving approach (sometimes organized on an A3 piece of paper)

- Six Sigma and DMAIC

- The 8D, which appeared at Ford and is often used in the North American and European auto industry.

Let’s call them PDCA 2.0.

Each framework has its strengths and weaknesses. The Toyota approach includes breaking down the problem into several distinct problems when applicable, which is a great tip. But it doesn’t explicitly request a definition of the metrics to improve and how they are collected (it should be done, but only those who received proper training in this framework know about it).

However, there are lots of similarities. And they are all based on PDCA.

How to Implement the 4 Phases of PDCA in Your Factory

PHASE 1: PLAN

The Plan phase contains many steps. It is important to spend time in this phase. Once the problem is properly defined and deeply understood, it is much easier to choose and apply the right countermeasure(s).

The steps in the Plan phase are:

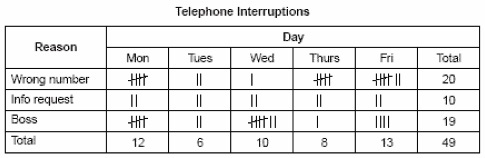

1. Collect quantitative and/or qualitative information

Gather some data about the problem. Does it appear consistently, in which circumstances, in which way, etc.

For example, occurrences can be written on a check sheet. It may show some obvious patterns.

Image courtesy of ASQ.org

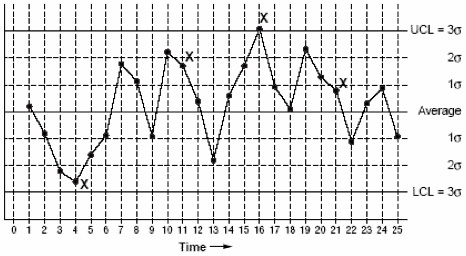

A control chart can also be used to collect data. It will show trends and patterns.

Image courtesy of ASQ.org

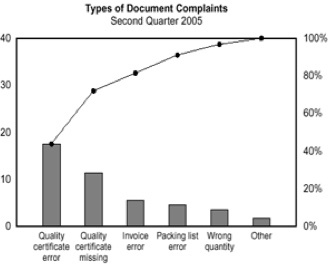

2. Analyze data and break down the problem

Try to find some trends, changes in trends, extreme values, etc. and find out why.

If the problem appears to be caused by many factors, break it down in to several sub-problems and continue this process on the sub-problem that seems to be the most important. (You can work on the other sub-problems in parallel, or keep them aside for later.) Root causes will be murky if you try to address several problems at the same time.

For example, a Pareto diagram will show what problems to focus on in priority.

Image courtesy of ASQ.org

3. Set a target

Once you have analyzed a problem, estimate what the gap is between the current status and the improved situation. Make sure to select metric(s) that are specific and can be measured.

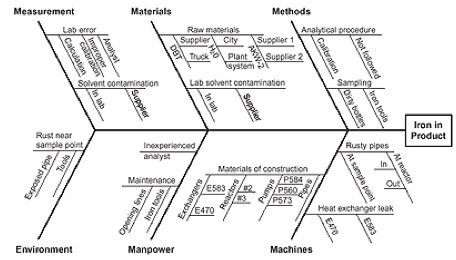

4. Determine the root cause(s) of the problem

Image courtesy of ASQ.org

Do not make any change that will not solve the problem permanently, or the same problem might come back next week. You need to get down to the root cause. A fish-bone diagram can be a good way of getting down to root causes. Another approach is to ask “why” 4 or 5 times.

5. Based on the root cause(s), determine some countermeasures

This should be relatively obvious. If a machine got out of specification, work on maintenance and process control. If an employee made a mistake, provide training and clear work instructions, and try to mistake-proof their work when possible.

PHASE 2: DO

Take the smallest steps you can to apply the countermeasure(s) and get a result that can be checked.

PHASE 3: CHECK

Compare current status to target and draw conclusions.

PHASE 4: ACT

If the countermeasure(s) you have implemented are effective in getting the result you wanted, make sure they will “stick”. You might have to make a change in management systems (internal audit checklists, visual boards, role of certain people…) to support the new way of doing things. In the long run, that’s how you fix your China factory!

Final Words

To sum up, solving production and quality issues and preventing their recurrence is hard for two reasons. First, it is hard work and time consuming. Second, the right approach does not come naturally to people.

Using templates and coaching engineers into following those templates is also hard work for management. And yet this is the way to answer the pertinent questions here: "How to fix my factory in China?"

The answer is to improve both your systems & processes and the ability of your staff to carry out improvement projects.

Have you used PDCA or PDCA 2.0 to fix your manufacturing operations in China? What went well, and what was challenging? Let us know if you have more issues and questions about fixing your factory or otherwise by leaving a comment below.