A lot of reading material online is full of advice on improving quality, efficiency, and lead times simultaneously. It's very inspiring, but how do we train quality and process engineers to take the proper steps for effective process improvement? First, let's look at the definition of process improvement.

What is Process Improvement?

Process improvement is a continuous process that involves discovering, assessing, and enhancing current organizational procedures to make sure your company is working at peak efficiency. Process improvement can take various forms, though it often adheres to a particular methodology. The most popular are the trio of lean manufacturing strategies, each concentrating on a specific area that needs optimization.

Art Smalley, President of Art of Lean, recently published a great book, Four Types of Problems: From Reactive Troubleshooting to Creative Innovation. He categorizes four types of problem-solving approaches—listing their pros and cons and when to pick each method. We found his advice to be highly applicable in day-to-day operations in manufacturing.

In this blog, we are covering one beneficial process improvement classification; countermeasures. Let’s say an issue comes up. What type of countermeasure will you put in place to prevent recurrence in the future?

3 Types of Countermeasures for Effective Process Improvement Management

1. Administrative Measures

Smalley gives the following examples: “job instruction or worker training, standardized work, inspection, audits, containment, visual aids, alerts, anything like that that gets posted as a way to affect the individual or remind people to do something”. In some cases, well-thought visual aids (for instance, color codes) can do wonders, and in many cases, it adds to paragraphs of text that nobody reads.

It is well-intentioned and could work as a short-term solution. If people do as prescribed, the issue it targets won’t come up again, or it will at least be detected and addressed early. However, have you analyzed the problem and identified one or two root causes? Have you done the more complex work of fixing the situation at the root? Probably not.

2. Detection Measures

If you can find a way to have the problem detected without relying on human work (inspection, an extra process step), it is usually cheaper, more reliable and more likely to stick in the long run.

As Smalley describes, “It goes farther and looks at the process and says, what can I do in the process with gauges, sensors, devices, techniques that automatically detect the problem situation, if and when it occurs, and stop it from getting out of the process and going downstream or to the customer or anything like that?” We gave many examples of error-proofing techniques before, and they fit in this category.

3. Prevention Measures

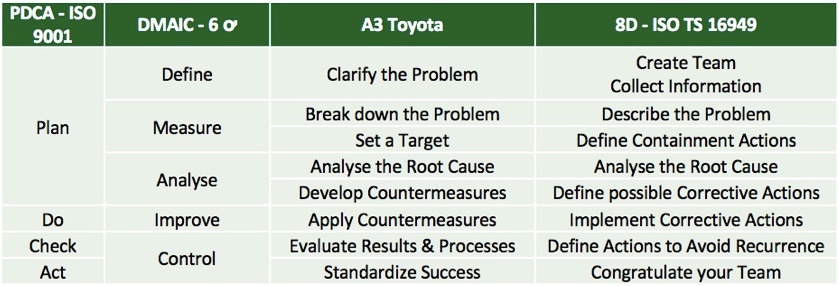

If you do the hard work of root-cause analysis and make adjustments to processes, you aim to make that issue disappear entirely. The table below shows a few frameworks and methodologies you can use for process improvement projects.

Of course, applying all this is easier said than done. People without relevant training often make the mistake of skipping essential steps. In Smalley’s words, “Prevention is best because it doesn't just administer the process through training or some other mechanism. It doesn't just detect the problem, but you're going after the real root cause and the underlying conditions and factors which allowed it to happen in the first place.”

The Bottom Line

To learn more about Administrative, Detection and Prevention measures and how you can put them into practice, you can watch Smalley's 2-part video series explaining these concepts in further detail. The first part describes each countermeasure in depth, while the second looks at how different COVID-19 responses fit within these three categories.

Are you ready to start implementing process improvement methodologies in your factory? Contact us today for a free consultation or read more below.

Over to you. Do you have any examples of these types of countermeasures in practice in your own factory?

If so, please share them in the comments below!